The Briggs & Stratton 675 Series engine is a reliable power source for lawn mowers and outdoor equipment, offering 190cc and 6.75 ft-lb torque. This manual provides a detailed parts diagram and guide for maintenance, repair, and troubleshooting, ensuring optimal performance and longevity of your engine.

1.1 Overview of the Briggs & Stratton 675 Series Engine

The Briggs & Stratton 675 Series engine is a 190cc, 6.75 ft-lb torque power unit designed for reliability and durability. Released in February 2011, it powers lawn mowers like the Toro model, offering consistent performance for outdoor equipment. This vertical shaft engine is part of the Quantum series, known for its robust design and efficiency. The 675 Series is widely used in gardening and landscaping applications, making it a trusted choice for homeowners and professionals. Its compact size and powerful output ensure it meets the demands of various tasks. With a focus on longevity, this engine is built to withstand heavy use while maintaining optimal performance.

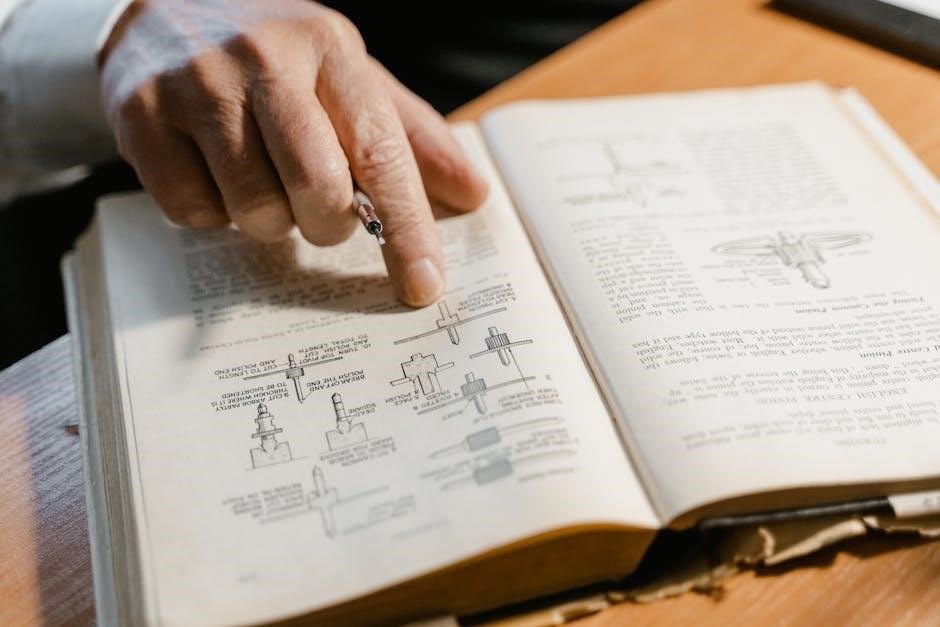

1.2 Importance of the Parts Diagram

The parts diagram for the Briggs & Stratton 675 Series engine is an essential tool for understanding and working with the engine. It provides a visual representation of all components, making it easier to identify and locate specific parts. This is crucial for maintenance, repairs, and troubleshooting, as it ensures accurate identification of replacement parts. By referencing the diagram, users can avoid confusion and ensure proper assembly or disassembly of engine components. It also serves as a guide for diagnosing issues, allowing users to pinpoint faulty parts quickly. Overall, the parts diagram enhances efficiency and accuracy, making it indispensable for anyone working with the Briggs & Stratton 675 Series engine.

Understanding the Parts Diagram

The parts diagram provides a visual breakdown of the engine’s components, using symbols and abbreviations to simplify identification. It is organized by major assemblies for easy navigation.

2.1 Layout and Structure

The Briggs & Stratton 675 Series parts diagram is organized into clear sections, making it easy to identify and locate components. The layout typically includes a detailed illustration of the engine, divided into major assemblies such as the cylinder head, crankshaft, and carburetor. Each part is numbered and cross-referenced with a corresponding parts list. The structure follows a logical flow, starting from the outer components and moving inward. Visual cues like color coding and exploded views enhance comprehension. The diagram also includes a table of contents and an index for quick navigation. This systematic approach ensures users can efficiently find and understand the location of specific parts, facilitating maintenance and repairs.

2.2 Symbols and Abbreviations

The Briggs & Stratton 675 Series parts diagram uses standardized symbols and abbreviations to represent components and their relationships. Common symbols include gears, electrical connectors, and fluid lines, while abbreviations like “HP” (horsepower) and “CC” (cubic centimeters) are frequently used. These symbols are consistent across all diagrams and are essential for identifying and locating parts accurately. Understanding these symbols is crucial for proper assembly, disassembly, and troubleshooting. A key or legend is often provided on the first page of the diagram to decode these symbols, ensuring clarity and ease of use for technicians and DIY enthusiasts alike. Always refer to this key to avoid confusion and ensure accurate interpretation of the parts diagram.

Engine Specifications

The Briggs & Stratton 675 Series engine features a 190cc displacement, 6.75 ft-lb torque, and vertical shaft design, ideal for lawn mowers and small outdoor equipment applications.

3.1 Model Number and Description

The Briggs & Stratton 675 Series engine is identified by model numbers such as 126M02-1006-F1, representing its vertical shaft design and 190cc displacement. This engine delivers 6.75 ft-lb of torque, making it suitable for lawn mowers and small outdoor equipment. Released in 2011, it is part of the Quantum series, known for reliability and consistent performance. The model number encodes critical specifications, ensuring compatibility with replacement parts and maintenance procedures. Understanding the model number is essential for accurately referencing the parts diagram and ensuring proper servicing. This engine is widely used in Toro lawn mowers and similar applications, emphasizing its versatility and durability in residential and light commercial settings.

3.2 Key Features and Applications

The Briggs & Stratton 675 Series engine is a 190cc, 6.75 ft-lb torque power unit designed for reliability and durability. It features an overhead valve (OHV) design for efficient performance and a vertical shaft configuration, making it ideal for lawn mowers, pressure washers, and other small equipment. Its compact size and lightweight design allow for easy integration into various applications, while its robust construction ensures long-lasting operation. The engine is widely used in residential and light commercial settings, providing consistent power for demanding tasks. Additionally, its easy maintenance and repair features make it a popular choice for DIY enthusiasts and professionals alike. This engine is a versatile and dependable option for outdoor power equipment needs.

Parts Identification

Identify engine components using the detailed parts diagram, which highlights major assemblies like the cylinder, carburetor, and crankshaft. Use the model number to locate specific parts effectively.

4.1 Major Components Overview

The Briggs & Stratton 675 Series engine consists of key components essential for its operation. These include the cylinder block, which houses the piston and crankshaft, and the carburetor, responsible for fuel-air mixture delivery. The air filter ensures clean air intake, while the fuel tank stores the necessary fuel. The ignition system, including the spark plug and coil, generates the spark for combustion. Additionally, the muffler reduces exhaust noise, and the cooling system prevents overheating. These parts work together to ensure efficient engine performance and reliability. Understanding their roles is crucial for proper maintenance and repair.

4.2 Locating Specific Parts

To locate specific parts in the Briggs & Stratton 675 Series engine, refer to the detailed parts diagram provided in the manual. Start by identifying the model number (e.g., 126M02-1006-F1) to ensure accuracy. Use the interactive lookup tool or the table of contents to navigate to the relevant section. Each part is numbered and labeled, corresponding to its position in the engine. For example, components like the air filter, muffler, or carburetor are highlighted with clear visuals. Cross-reference the part number with the list to confirm its location. This method ensures precise identification, avoiding confusion and saving time during repairs or replacements.

Maintenance and Servicing

Regular maintenance ensures optimal performance. Routine procedures include oil changes, air filter cleaning, and spark plug checks. Refer to the parts diagram for specific service intervals and guidelines.

5.1 Routine Maintenance Procedures

Regular maintenance is essential to ensure the optimal performance and longevity of your Briggs & Stratton 675 Series engine. Start by checking the oil level regularly and changing it every 50 hours of operation. Clean or replace the air filter as needed to maintain proper airflow. Inspect the spark plug for wear or fouling and replace it annually or as specified in the parts diagram. Check the muffler for blockages and ensure all bolts and fasteners are tightened securely. Refer to the illustrated parts list for guidance on locating these components. Schedule routine maintenance every 100 hours, including sharpening the mower blade and lubricating moving parts. Always use genuine Briggs & Stratton parts for compatibility and reliability. Following these steps will help prevent issues and keep your engine running smoothly.

5.2 Troubleshooting Common Issues

Troubleshooting the Briggs & Stratton 675 Series engine begins with identifying symptoms like poor start, low power, or overheating. Use the parts diagram to locate components such as the air filter, spark plug, and fuel system. Check for blockages or wear in the filter and ensure the spark plug is clean and properly gapped. Verify fuel flow and oil levels, as insufficient lubrication can cause engine failure. If issues persist, consult the manual for diagnostic steps or repair guides. Always refer to the parts diagram to ensure correct part identification and replacement. Regular maintenance and timely repairs can prevent major breakdowns and extend engine lifespan.

Repair and Replacement

This section guides you through identifying faulty parts and replacing them. Refer to the parts diagram for precise locations and follow step-by-step instructions for safe repairs.

6.1 Identifying Faulty Parts

Identifying faulty parts in the Briggs & Stratton 675 Series engine begins with consulting the parts diagram to locate the specific component. Use the Illustrated Parts List (IPL) to cross-reference part numbers and descriptions. Common issues include worn piston rings, faulty spark plugs, or damaged carburetors. Look for signs like excessive vibration, oil leaks, or reduced performance. Always verify the problem by checking the part against the diagram and manual specifications. Ensure replacements match the manufacturer’s part numbers for compatibility. This systematic approach helps pinpoint and address issues efficiently, ensuring proper engine functionality.

6.2 Step-by-Step Repair Guide

To repair your Briggs & Stratton 675 Series engine effectively, start by consulting the parts diagram to identify the faulty component. Begin with basic troubleshooting: disconnect the spark plug, inspect the air filter, and check oil levels. If issues persist, examine the carburetor and fuel lines for blockages or damage. For major repairs, such as replacing the cylinder head or crankshaft, ensure you have the correct tools and follow the manufacturer’s torque specifications. Always refer to the parts manual for precise instructions. After completing repairs, reassemble the engine carefully and test it to ensure proper function. Regular maintenance and timely repairs will extend the engine’s lifespan and performance.

Installation Guide

Ensure proper installation by verifying compatibility, checking for damaged parts, and following the provided parts diagram. Prepare tools and consult the manual for specific instructions.

7.1 Pre-Installation Checklist

Before installing your Briggs & Stratton 675 Series engine, ensure you have all necessary components and tools. Review the parts diagram to confirm all items are included and undamaged. Verify the engine model number matches your equipment specifications. Inspect the engine and mounting hardware for any signs of damage or wear. Gather essential tools, such as wrenches, sockets, and torque specifications. Prepare a clean, stable workspace to avoid contamination or accidents. Refer to the manual for specific torque values and installation sequences. Ensure all safety precautions, like disconnecting the spark plug, are followed. Double-check the alignment of mounting points and electrical connections; Consult the troubleshooting section if any issues arise during preparation. By following this checklist, you can ensure a smooth and successful installation process.

7.2 Installation Process

Begin by preparing the engine and ensures all components are aligned correctly. Mount the engine securely, following the manufacturer’s torque specifications. Connect the carburetor, air filter, and spark plug wire. Attach the throttle and choke cables to the appropriate ports. Ensure proper fuel line connections and verify the oil level. Tighten all bolts and screws systematically to avoid misalignment. Test the engine by turning the ignition and checking for smooth operation; Refer to the parts diagram for accurate placement of each component.Finally, conduct a test run under no load to ensure everything functions correctly before full operation.

Safety Precautions

Always wear protective gear, ensure proper ventilation, and avoid overheating. Disconnect the spark plug before servicing to prevent accidental start-ups and ensure a safe working environment.

8.1 Handling and Safety Tips

When working with the Briggs & Stratton 675 Series engine, always wear protective gear, including gloves and safety glasses, to prevent injury. Ensure the engine is cool before handling to avoid burns. Properly lift heavy components to prevent strain or damage. Store small parts in a secure, dry place to avoid loss or contamination. Avoid overheating the engine during operation, as this can lead to premature wear. Use only approved tools and follow recommended torque specifications to prevent damage to threads or components. Keep loose clothing and long hair tied back to avoid accidents. Always refer to the safety guidelines in the manual for specific precautions tailored to your engine model.

8.2 Protective Gear and Environmental Considerations

When working with the Briggs & Stratton 675 Series engine, always wear appropriate protective gear, including gloves, safety goggles, and a face mask, to minimize risks of injury. Ensure proper ventilation to avoid inhaling harmful fumes. Dispose of hazardous materials like oil and batteries responsibly to protect the environment. Recycle parts whenever possible and follow local regulations for waste disposal. Keep the workspace clean to prevent accidents and environmental contamination. Adhering to these guidelines ensures both personal safety and eco-friendly practices during maintenance, repair, or installation of engine parts. Always refer to the manual for specific safety recommendations tailored to your task.

Frequently Asked Questions

9.1 Common Queries About the Parts Diagram

- Where can I find the Briggs & Stratton 675 Series parts diagram?

- How do I identify specific parts using the diagram?

- Are replacement parts compatible with my engine model?

9.2 Additional Resources for Further Assistance

Visit the official Briggs & Stratton website for downloadable manuals, troubleshooting guides, and interactive parts lookup tools.

Users often inquire about locating specific parts, understanding symbols, and interpreting the diagram layout. Frequently asked questions include how to identify replacement parts, decode model numbers, and navigate the parts list. Many seek clarification on abbreviations and symbols used in the diagram. Others ask about accessing downloadable PDF versions of the parts manual. Additionally, troubleshooting common issues, such as missing parts or unclear labels, is a prevalent query. The parts lookup tool is also a popular topic, as it helps users find exact replacement components. These questions highlight the importance of a clear, user-friendly parts diagram for effective maintenance and repairs.

For further assistance with the Briggs & Stratton 675 Series parts diagram, explore official resources like the Briggs & Stratton website, which offers downloadable PDF manuals and illustrated parts lists. Utilize their Parts Lookup Tool for identifying specific components. Additionally, community forums and repair websites provide DIY guides and troubleshooting tips. GitHub repositories, such as na520/Briggs-Stratton-675-Series-Parts-Diagram, offer free access to repair manuals and schematics. For hands-on support, consult local small engine repair shops or authorized Briggs & Stratton service centers. These resources empower you to maintain, repair, and optimize your engine effectively.